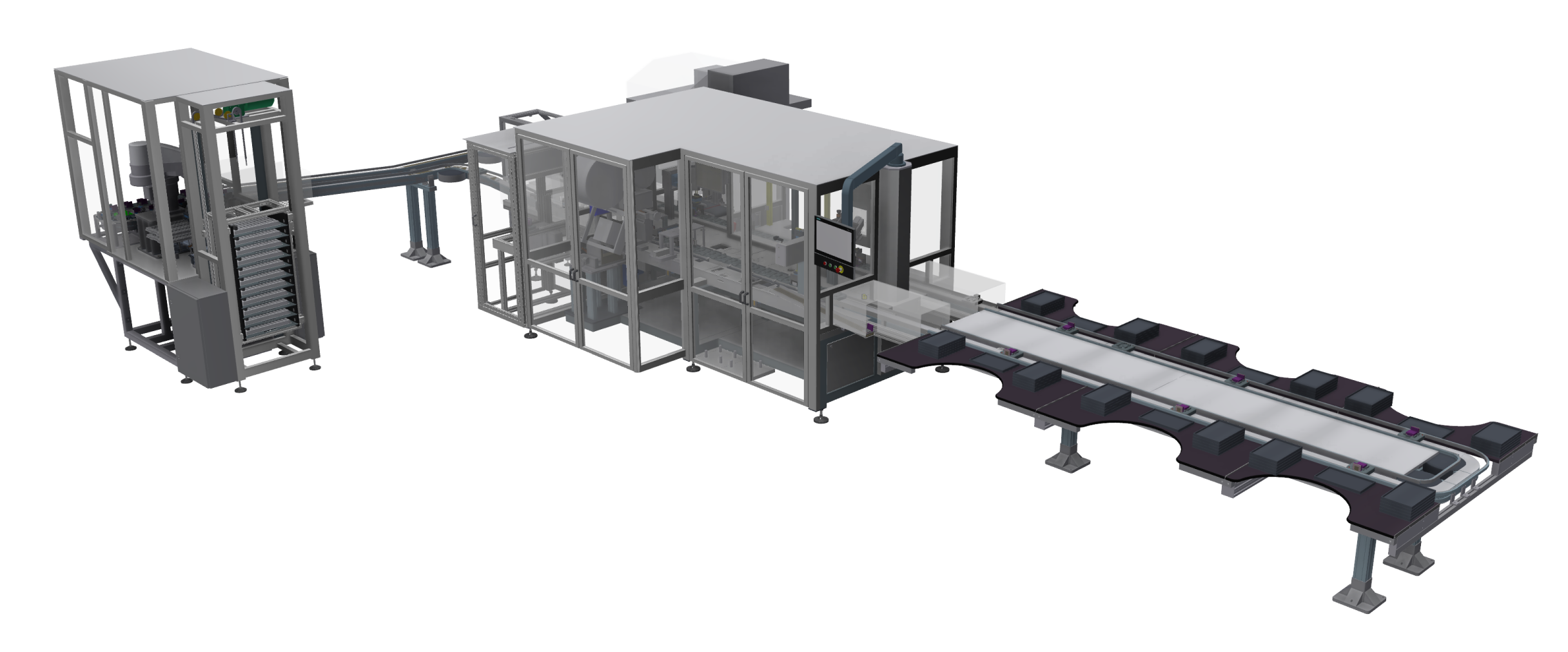

The assembly of make-up boxes

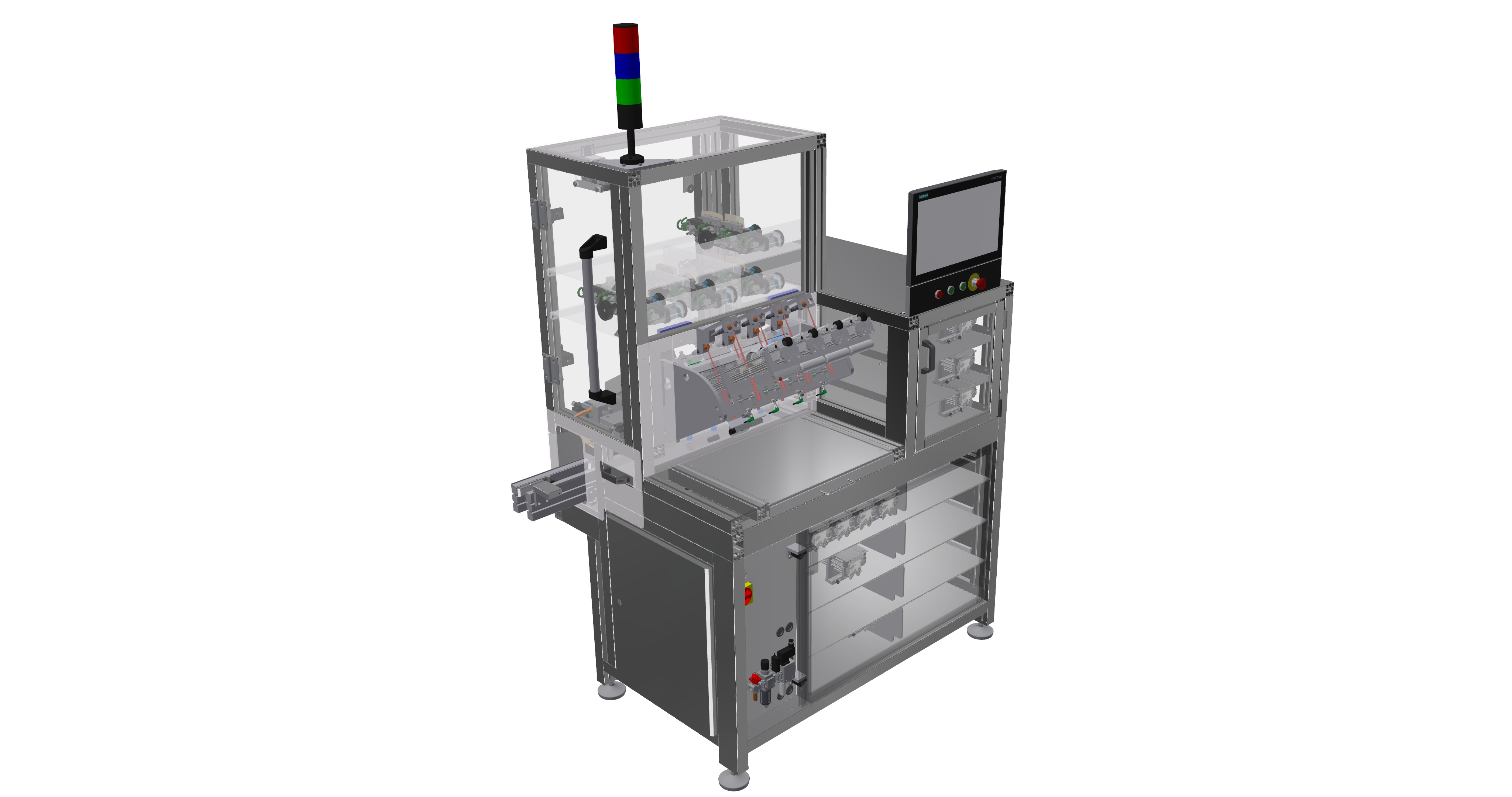

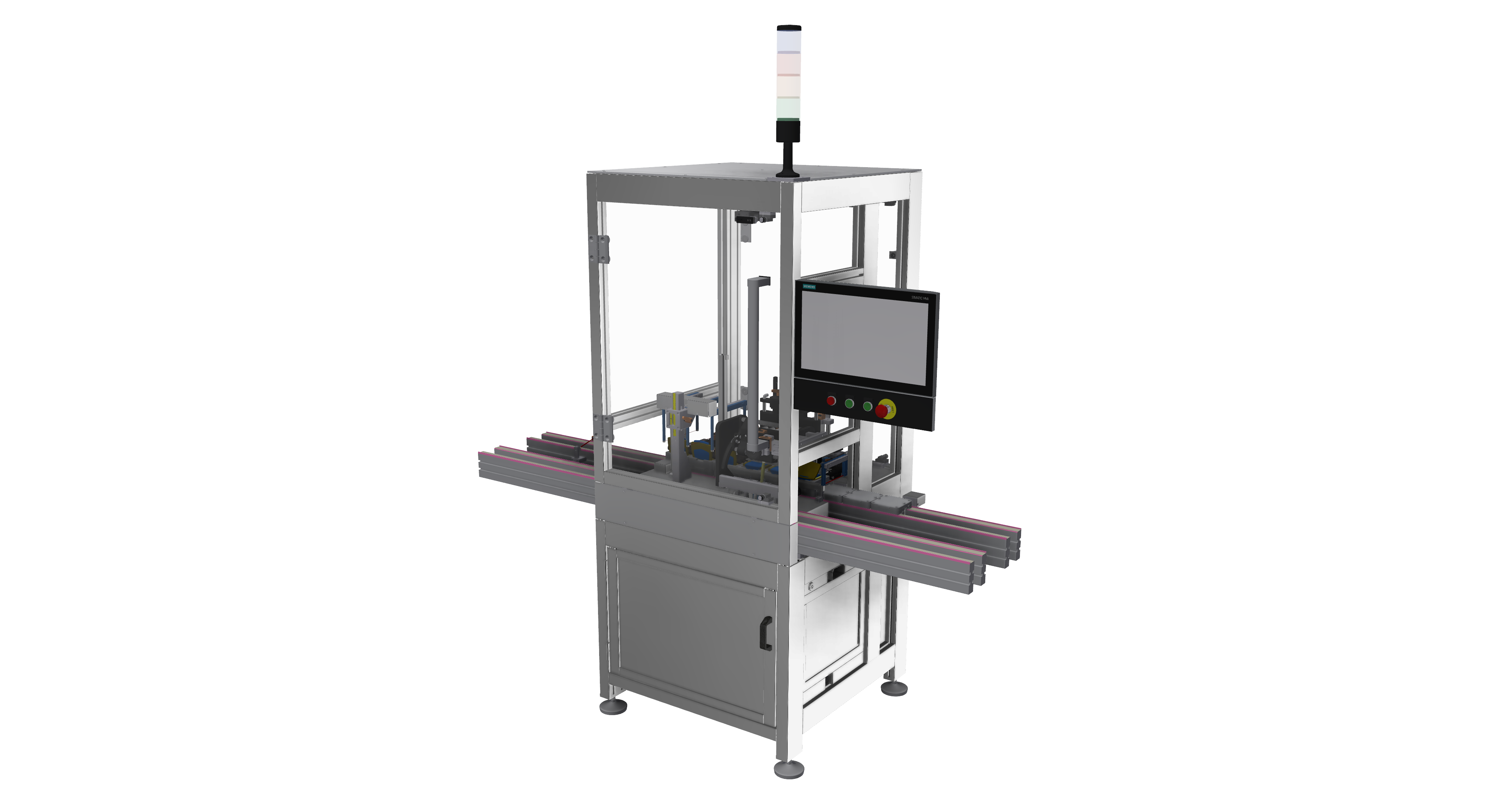

Each make-up palette has its own method of assembly. We specialise in made-to-measure solutions, which is why we adapt the functions of the machine according to the characteristics and constraints of the case: depositing make-up cups, applying protective covers, labelling or others.

Make-up pallets can sometimes include more than 16 colours, have brushes or mirrors. This is why we frequently integrate industrial robots of the “Pick And Place” Scara or Delta type. These are agile and are able to deposit precisely in record time. Associated with a vision system, the robots allow the unitary placement of the components directly in the thermoformed parts.